1984

Thrustmaster of Texas, Inc. is founded in Houston, Texas, by Joe R. Bekker who is still the President and CEO of the company.

The first order, a self-contained diesel-driven propulsion unit for mounting on the deck of a barge, is produced for the U.S. Army Corps of Engineers.

1985

The U.S.

Navy orders four propulsion units for a crane barge.

Hydraulic tunnel thrusters are produced for several military

and commercial customers.

1987

The U.S. Army orders thirteen self-contained diesel-hydraulic propulsion units for floating causeway application.

1988

The first Portable Dynamic Positioning System PDPS is installed on a treasure hunting vessel, the Arctic Discoverer, which successfully locates the S.S. Central America and recovers an estimated USD 150-million in gold. Ellicott dredges are outfitted with fixed hydraulic podded thrusters. A radio-controlled propulsion unit is installed on a bow boat used by Breathwit Marine Contractors for better navigation of barge trains through rivers and canals.

1989

Clean-up contractors order fourteen diesel driven propulsion units for the Alaska oil spill in Valdez, AK. A car ferry crossing the Mekong River in Laos is provided with diesel-hydraulic Thrustmaster propulsion units. Breaux Brothers orders aluminum tunnel thrusters for crewboats.

1990

The U.S. Army Corps of Engineers continues to buy propulsion units of different sizes and configurations. Hydraulic tunnel thruster business grows rapidly for use in OSV’s, dinner cruise vessels, river casino boats and tugs. Thrustmaster moves to larger manufacturing facilities.

1991

The first Thrustmaster azimuthing Z-drives for tug boats are installed at Bernert Tug and Barge Lines. The Navy of Pakistan joins the growing list of military users of Thrustmaster propulsion units. More units are shipped to customers in Guyana, Korea, Indonesia and Singapore. Thrustmaster rapidly is becoming a major thruster manufacturer in the world commercial marine market.

1992

Alcatel buys a PDPS for a cable lay barge in Thailand. Matson Navigation orders an azimuthing retractable stern thruster with radio control for one of their towed ocean-going barges. Baker Marine in Singapore orders azimuth drives for self-propulsion of a jack-up rig. The U.S. Air Force buys Thrustmaster propulsion units for offshore bases. The U.S. Navy orders propulsion units for torpedo testing barges. Thrustmaster is elected “Exporter of the Year” by the U.S. Small Business Administration.

1993

Many casino boat projects with through-hull azimuth Z-drives and large hydraulic tunnel thrusters. The Marine Spill Response Corporation (MSRC) orders seventeen self-contained diesel-hydraulic propulsion units with integrated pilot house, mast, oil skimmer drives and many other features. Global Industries installs retractable azimuth thrusters in one of their large pipe lay barges. Sales now exceed ten million dollars. Thrustmaster doubles its manufacturing space.

1994

The Navy of Pakistan orders more self-propelled deck mounted units for barges. The U.S. Navy Underwater Warfare Center (NUWC) orders diesel-hydraulic propulsion units for sonar research program. Thrustmaster continues to supply many tunnel thrusters for casino boat projects. Western Geophysical orders diesel-hydraulic propulsion units for operations in Kazakhstan.

1995

Thrustmaster Z-drives and podded non-steerable drives are used on long-range trawler yachts built by Cape Horn Trawler Corporation and others. Edison Chouest Offshore buys Thrustmaster steerable drop-down thrusters for station-keeping of their large aluminum fast supply vessels. Many diesel-hydraulic propulsion units are built for brown water barge applications for river transport in Alaska, South America, Africa and the Far East.

1996

Pirelli orders PDPS thruster system for cable-lay barges used in shore approaches and shallow water trench-lay-bury operations. International business is growing fast with thrusters for OSV’s in Malaysia, fishing vessels in Peru, transport barges in Ecuador, fast ferries in Australia, an offshore construction barge in England, a SWATH vessel in Hong Kong, a cruise vessel on the Thames River, car ferries in Chile and Egypt, a tanker in South Africa and split-hopper barges in Indonesia.

1997

U.S. Navy uses the PDPS for diving support. Tug projects in Mexico and Venezuela, many OSV and PSV thrusters for dynamic positioning, retractable azimuth thrusters for tanker application. Thrustmaster’s Chief Engineer, Dr. Shaw Dou, Ph.D, brings ANSYS Finite Element Analysis into the company. Thrustmaster moves to a larger factory.

1998

Seacor Marine orders retractable bow thrusters for their large aluminum crew/supply vessels. Delba Maritima in Brazil orders PDPS thrusters for dynamic positioning conversion of an OSV. Western Geophysical buys large propulsion unit packages for survey barges at Alaska’s North Slope. Refinery Terminal Fire Company in the Port of Corpus Christi orders azimuthing thrusters to dynamically position a large fire-fighting barge. Many thruster orders from all over the world. Thrustmaster now the largest thruster manufacturer in the U.S. and one of the largest in the world.

1999

Seacor Marine places new orders for retractable thrusters for its new-build fleet improvement program. A second PDPS delivered to Pirelli for cable-lay barge conversion to dynamic positioning. Hydraulic tunnel thrusters are ordered by numerous shipyards for tuna fleet expansion in Mexico. U.S. Army Corps of Engineers continues to order deck-mounted propulsion units. The first jet thruster delivered to Baltimore Marine Industries.

2000

At the turn of the Millennium, Thrustmaster is well established as a world leading manufacturer of marine propulsion equipment for the 21st Century. Several large vessels are converted to dynamic positioning class using Thrustmaster electric or hydraulic thrusters. More harbor tug operators order azimuthing Z-drives for new tugs and retractable azimuth thrusters for upgrades of older tugs. Several PDPS ordered for barge conversions operating in the Pacific Rim.

2001

Owen Traylor joins Thrustmaster as General Manager who introduces significant improvements in customer service. Many PDPS systems are ordered by customers all over the world.

2002

Thrustmaster receives ISO-9001 certification. Builders of OSV’s crewboats, tugs, ferries and military vessels place orders in record numbers. Six 2,000 HP azimuthing Z-drives delivered for escort tugs on contract to the U.S. Navy for surface ship and submarine docking services. Seacor Marine continues their fleet improvement program with Thrustmaster’s thrusters. Thrustmaster expands its manufacturing facilities again.

2003

Thrustmaster’s quality system is upgraded to ISO-9001:2000 by the American Bureau of Shipping (ABS) Quality Evaluations. Thrustmaster continues to grow into a world leading marine propulsion manufacturer. Thrustmaster wins contract to provide thrusters for the U.S. Army Logistical Support Vessel (LSV) program.

2004

Continuous but controlled growth leads to record numbers of thruster orders. Many azimuthing Z-drives ordered for ASD tug fleet improvement programs. Egyptian government places an order for 270 self-contained propulsion units. More PDPS ordered by operators in the Pacific Rim. Thrustmaster wins contract to supply thrusters for the U.S. Navy’s Littoral Combat Ship (LCS) program.

2005

Thrustmaster receives ABS Manufacturing Assessment Certificate and "Type Approval Certificates" on standard models of hydraulic tunnel thrusters. PDPS hydraulic thrusters now produced up to 2,000 horsepower each (1,500 kW).

2006

Many hydraulic thrusters and self-contained power units of 1,000, 1,500, and 2,000 horsepower ordered for various conversions to dynamic positioning. U.S. Military Sealift Command leases PDPS for deck barge. Large azimuthing thruster orders for drilling platforms. Thrustmaster now producing thrusters up to 8,000 horsepower (6,000 kW).

2007

Thrustmaster receives record number of orders for large electrically-driven thrusters for drilling applications. Design of the new 200,000 square foot thruster factory begins. Thrustmaster receives “Subcontractor of the Year Award” from the U.S. Small Business Administration for its work on the U.S. Navy LCS program. Annual sales now exceed USD 100-million. Computational Fluid Dynamics (CFD) programs are added to Thrustmaster’s suite of design tools.

2008

Thrustmaster continues forward with new factory breaking ground in May 2008. Two retractable DP azimuth thrusters are installed in the Seacor Cheetah high speed catamaran crew boat. Signs new contracts leading to mechanical geared drives of 5000 to 6000 hp while continuing to produce record numbers of Portable Dynamic Positioning Systems. Field offices are opened in Europe, the Middle East, and Singapore.

2009

New 200,000 square foot thruster factory and 40,000 square foot design and administration facility completed. Increased engineering and manufacturing capacity including addition of dedicated MRP-II/ERP manager and manufacturing engineering manager. Field office opened in Rio de Janeiro, Brazil.

2010

Engineering department continues adding new talent and expanding software analysis tools. Order of over 200 hydraulic barge thrusters delivered to Army Corp of Engineers. Deliveries of TH5000ML drives begin.

2011

Thrustmaster opens office in Mumbai, India. Annual sales top USD$150M. Jim Jennings comes aboard as the new General Manager and begins cultivating teams.

2012

Zeiss Computerized Coordinate Measuring Machine is installed as QC continuously improves manufacturing feed back program. Installation of a Hankook VTL and a Union Chemnitz DV60 CNC Center begins.

2014

Thrustmaster expands product lineup to include waterjets. To meet the demands of large scale,

commercial applications, Thrustmaster introduced two new models to the waterjet product lineup. The 400 / 450 series Thrustmaster

waterjets will extend the power range from 100kW to 6,400kW.

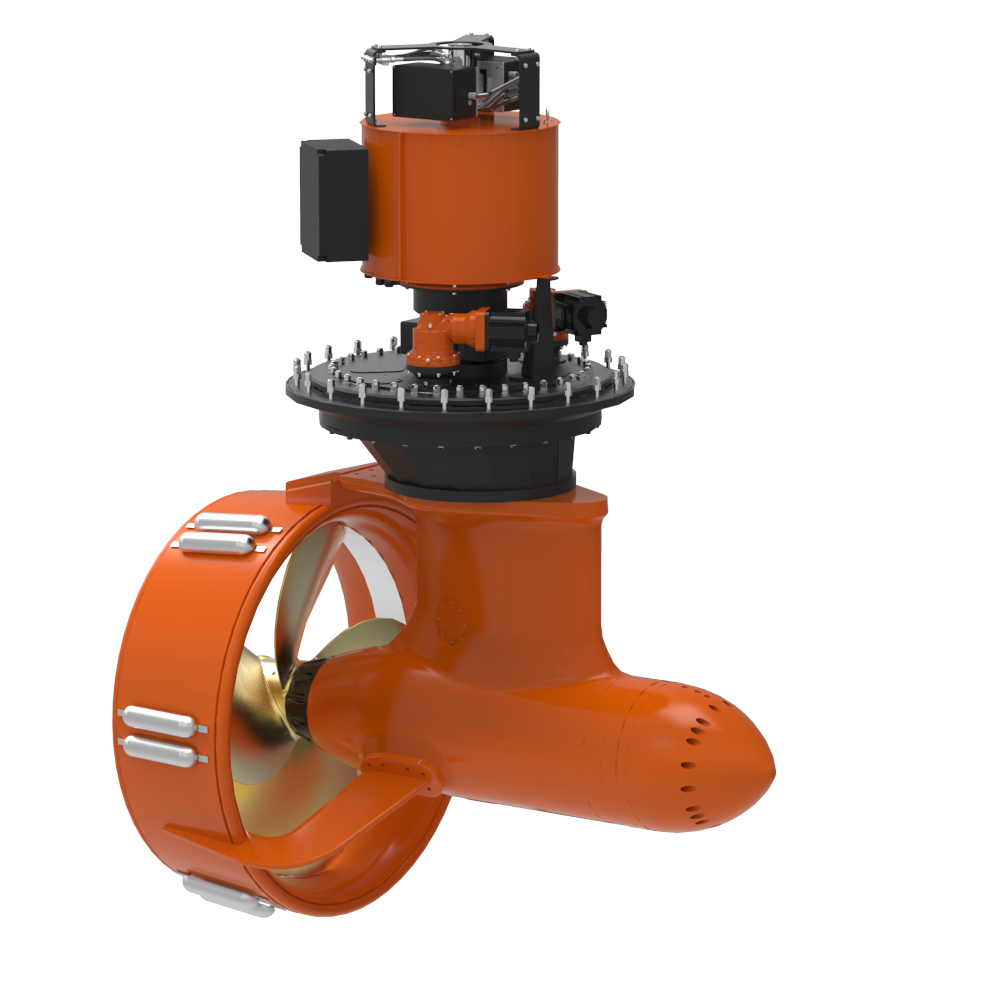

Azimuth Thrusters

360° rotating Azimuth thrusters are used when enhanced maneuverability is required in applications such as dynamic positioning, ship escort, and ship docking services.

Azimuth Thrusters

360° rotating Azimuth thrusters are used when enhanced maneuverability is required in applications such as dynamic positioning, ship escort, and ship docking services. Portable Dynamic Positioning

Quick dock-side conversion of any vessel to DP-0 thru DP-3 per any of the major classification societies.

Portable Dynamic Positioning

Quick dock-side conversion of any vessel to DP-0 thru DP-3 per any of the major classification societies. Outboard Propulsion Units

Outboard propulsion units are self-contained thruster packages for main propulsion and positioning of barges, platforms and river craft.

Outboard Propulsion Units

Outboard propulsion units are self-contained thruster packages for main propulsion and positioning of barges, platforms and river craft. Retractable Thrusters

Thrustmaster retractable thrusters are thru-hull azimuthing thrusters using fixed pitch propellers at variable speed.

Retractable Thrusters

Thrustmaster retractable thrusters are thru-hull azimuthing thrusters using fixed pitch propellers at variable speed. Water Jets

Axial flow water jets from 100kW to 6,400 kW available in 15 model sizes to accommodate vessels from 6m to +60m with stainless steel jets supported by electronic controls.

Water Jets

Axial flow water jets from 100kW to 6,400 kW available in 15 model sizes to accommodate vessels from 6m to +60m with stainless steel jets supported by electronic controls. Tunnel Thrusters

Tunnel thrusters for docking, slow speed maneuvering, emergency steering, and station keeping at zero or slow forward speeds.

Tunnel Thrusters

Tunnel thrusters for docking, slow speed maneuvering, emergency steering, and station keeping at zero or slow forward speeds. Portable River Ferry

Turn-key modular package comprised of interlocking barge sections with ramps on both ends, self-contained hydraulic outboard propulsion units, a raised pilot house, and all necessary accessories.

Portable River Ferry

Turn-key modular package comprised of interlocking barge sections with ramps on both ends, self-contained hydraulic outboard propulsion units, a raised pilot house, and all necessary accessories. Hybrid Propulsion Systems

Turn-key patented and proven hybrid propulsion packages offering a seamless integration with the vessel. Designs tailed to the vessel size, speed, transit route, and operational profile.

Hybrid Propulsion Systems

Turn-key patented and proven hybrid propulsion packages offering a seamless integration with the vessel. Designs tailed to the vessel size, speed, transit route, and operational profile. T-Pod Electric Podded Thrusters

Thrustmaster T-Pods are configured with a permanent magnet motor directly driving the propeller shaft in a pod housing.

T-Pod Electric Podded Thrusters

Thrustmaster T-Pods are configured with a permanent magnet motor directly driving the propeller shaft in a pod housing. Floatmaster

Floatmaster is a sister company of Thrustmaster of Texas, Inc., a world recognized designer and manufacturer of marine propulsion systems.

Floatmaster

Floatmaster is a sister company of Thrustmaster of Texas, Inc., a world recognized designer and manufacturer of marine propulsion systems.