By: Johnray Strickland

Thrustmaster of Texas, a leading marine propulsion design and manufacturing company based in the U.S., is looking to give a competitive edge to U.S. towboat operators considering a move away from traditional shaft and rudder installations via Thrustmaster’s impressive lineup of American made Z-Drives.

Thrustmaster’s Z-Drives, ranging from 500 hp to 8,000 hp, have been designed and built to handle the demanding conditions of the inland waterways.

The inland waterways industry has reached a tipping point with acceptance of Z-Drives for future vessel builds. Initial adopters such as Southern Towing Company and the Carline Company have come back lauding the results.

Vastly improved maneuverability without rudders

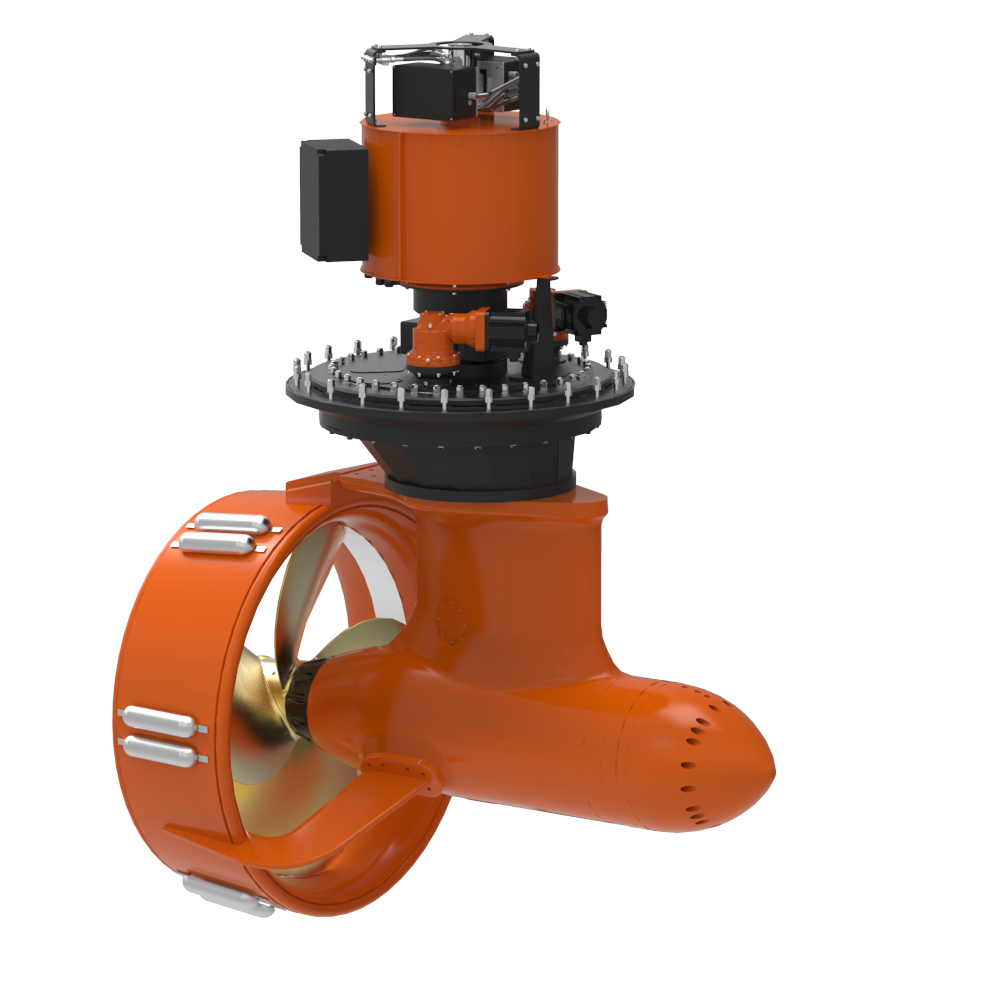

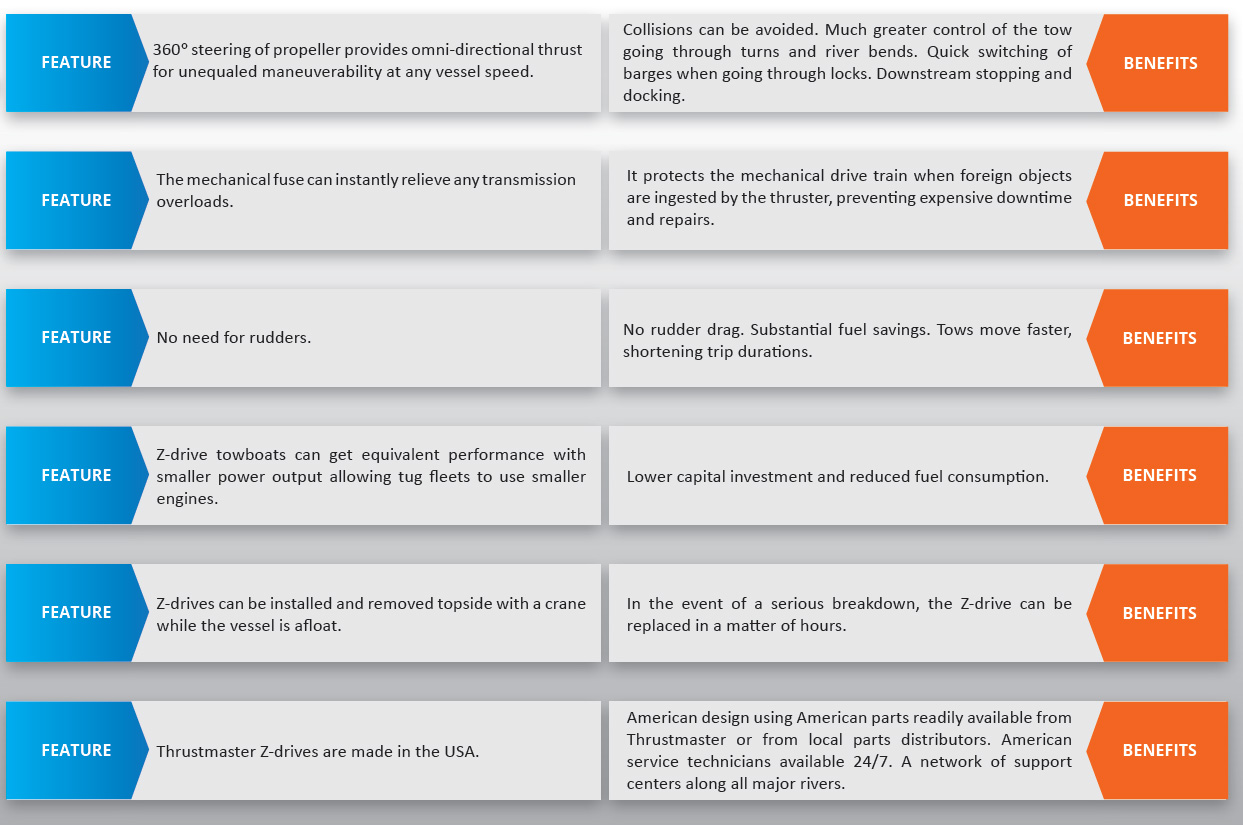

A Z-drive replaces the propeller, shaft, stern tube, marine gear, rudder and steering gear all with a single unit. Z-Drive azimuthing thrusters provide maximum thrust in any direction, independent of vessel speed, offering superior pinpoint maneuverability under all conditions. Rudders are completely eliminated. Rudder drag no longer exists. All of this can be done with a lot less power. A 1,500HP Z-drive boat can replace a 2,000HP conventional towboat and a 3000HP Z-drive boat can replace a 4,000HP conventional towboat.

Safer, faster, using less fuel

Due to the greatly improved maneuverability with Z-drives, costly collisions can be avoided. There is no longer any need to slow down in turns and bends in the river. Trip times are reduced and require a lot less fuel. A study conducted by The Shearer Group, Inc. showed an average of 28% fuel savings and 11% trip time savings during a set of controlled experiments with unit tows when using Z-Drives instead of conventional shafts and rudders.

Simple and clean towboat design

Z-drives require little space. The complete Z-drives drop in from the top. The absence of long propeller shafts, shaft alleys, steering gears and rudders greatly reduces the required machinery space and weight, thus increasing the usable volume and payload of the vessel. The need for propeller shaft alignment is eliminated.

Unparalleled Support throughout the Entire Life of the Thruster

Unparalleled Support throughout the Entire Life of the Thruster

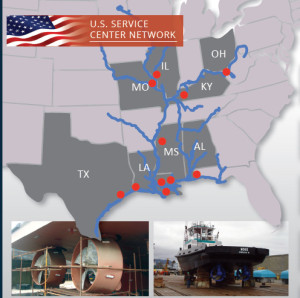

In order to ensure optimum service with minimal response times, Thrustmaster has an extensive service network with service centers strategically located along the major rivers in the USA. Experienced service technicians are available to provide installation, commissioning, maintenance, repairs and upgrades on our propulsion and control products. Thrustmaster maintains a large inventory of spare parts at all times. Current parts inventory in our Houston plant is almost $30 million stocked and ready to go when needed.

“What sets us apart in the marine propulsion industry is our dedication to quality, service and the commitment to treating our customers as our business partners,” said Thrustmaster of Texas, Inc. President Joe Bekker. “Not only do we know the marine market, we actively listen to our customer’s requirements and apply that knowledge to product development and improvement. At Thrustmaster, we constantly strive for the continuous improvement in the quality and value of our products.”

Thrustmaster’s exceptional American quality translates perfectly to the demanding conditions of America’s waterways.

The Carline Company’s latest towboat, the USS Cairo, is equipped with two Thrustmaster TH750MZN 750 hp Z-Drives. Carline offers fleeting services in Louisiana on the Lower Mississippi River at Burnside, Geismar and Plaquemine where the company’s new 68’×34’×10′ fleet towboat will be used.

The Carline Company’s latest towboat, the USS Cairo, is equipped with two Thrustmaster TH750MZN 750 hp Z-Drives. Carline offers fleeting services in Louisiana on the Lower Mississippi River at Burnside, Geismar and Plaquemine where the company’s new 68’×34’×10′ fleet towboat will be used.

“This is the first boat that we’ve had built that is specifically for fleeting operations,” said Clay Harmon, Carline’s vice president. “We’ve always used some of our older linehaul boats as fleet boats, and they work fine. But this boat increases the efficiency in the fleet. It also increases safety because its two Z-drives give the vessel added control.”

An example of added control and increased productivity is the maneuver called downstreaming. Downstreaming highlights a unique challenge faced daily by fleet operators whereby a fleet boat takes selected barge(s) off a large tow and puts them in the fleet. Depending on where the tow stopped in the river, the fleet boat may have to travel down river, turn around, and come back to put the barge(s) in the fleet safely, all of which takes time. By taking the barge(s) directly to the fleet using a downstream approach takes less time but with a rudder and propeller fleet boat can be a difficult maneuver. By using a z-drive fleet boat, shifting times (and the fuel used) can be reduced by half with the additional benefit of increased safety of the customer’s barges, fleet boat, and crew.

“I would say that the main difference between this boat and the other fleet boats is better maneuverability, it’s definitely better,” said USS Cairo Capt. John Michot, of the Carline Company.

“I would say that the main difference between this boat and the other fleet boats is better maneuverability, it’s definitely better,” said USS Cairo Capt. John Michot, of the Carline Company.

Robust and Reliable. Designed and built in America.

Thrustmaster knows and understands brown water applications. We have been building brown water propulsion equipment for more than 30 years. Thrustmaster Z-drives are designed based on conservative American standards observing ample safety margins. They are built to last even in the harshest operating environment. The units are built

in our headquarters facility in Houston, Texas, using American materials, American components and American labor.

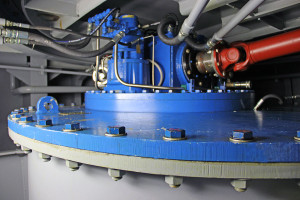

Each Z-drive is equipped with a husky stainless steel propeller running in a nozzle with stainless steel internals. The gears and transmission shafts are generously sized and are protected by a quick release coupling at the input shaft of the Z-drive. This quick release coupling acts as a mechanical fuse whenever the drive line is blocked, for instance when the propeller ingests a log, a tire or a rope. The mechanical fuse can be reset manually after the obstruction is removed out of the propeller.

Easy Maintenance

Routine maintenance is limited to periodic replacement of filter elements for the lubricating oil and the steering hydraulic fluid. Whenever major maintenance or repair is required, the complete Z-drive is lifted out of the vessel while the vessel is afloat. A replacement Z-drive can be dropped in and the boat is back to work within hours.

The current 200,000 sqft thruster factory with in-house fabrication, machining, assembly, inspection and testing capabilities opened in 2009 in Houston, TX and continues to be a preeminent thruster manufacturing facility in the world. Thrustmaster, never content with the status quo, has reinvested each year in new machining technology and quality control to elevate the caliber of thruster products delivered to their customers.

With well over 1,000 thruster units in operation around the world, many of them of an exclusive design to suit a particular unique application, Thrustmaster demonstrates its dedication to design engineering excellence as well as service after installation. Thrustmaster Z-drives are engineered products of American design based on the latest U.S. technologies, ANSYS Finite Element Analysis, and the most modern manufacturing technologies. Thrustmaster’s flexible engineering and design standards lead to maximum operational performance.

The initial cost of azimuthing thrusters is significantly offset by reduced construction costs and installation man-hours: intermediate and propeller shafts, reduction gear boxes, shaft couplings, hydraulic pumps and rams with all their piping, rudder tubes and bearings, steering and flanking rudders, stern tube bearings and seals, and struts and strut bearings are eliminated. The thrusters may be located at the optimal astern position, often resulting in propulsion efficiency. Modular construction, incorporating proven mechanical, hydraulic, and electrical sub-assemblies, ensure a totally reliable integration of the propulsion and steering systems in the vessel.

The initial cost of azimuthing thrusters is significantly offset by reduced construction costs and installation man-hours: intermediate and propeller shafts, reduction gear boxes, shaft couplings, hydraulic pumps and rams with all their piping, rudder tubes and bearings, steering and flanking rudders, stern tube bearings and seals, and struts and strut bearings are eliminated. The thrusters may be located at the optimal astern position, often resulting in propulsion efficiency. Modular construction, incorporating proven mechanical, hydraulic, and electrical sub-assemblies, ensure a totally reliable integration of the propulsion and steering systems in the vessel.

Thrustmaster’s unique design features a very low input shaft height. The low input shaft elevation facilitates lower main deck elevation. Both sets of right angle spiral bevel gears are designed for continuous operating at maximum torque condition.

Maximum maneuverability, optimum efficiency, reliable and economical operation, and easy maintenance are the outstanding features of Thrustmaster’s series of Z-Drives.