- Products

-

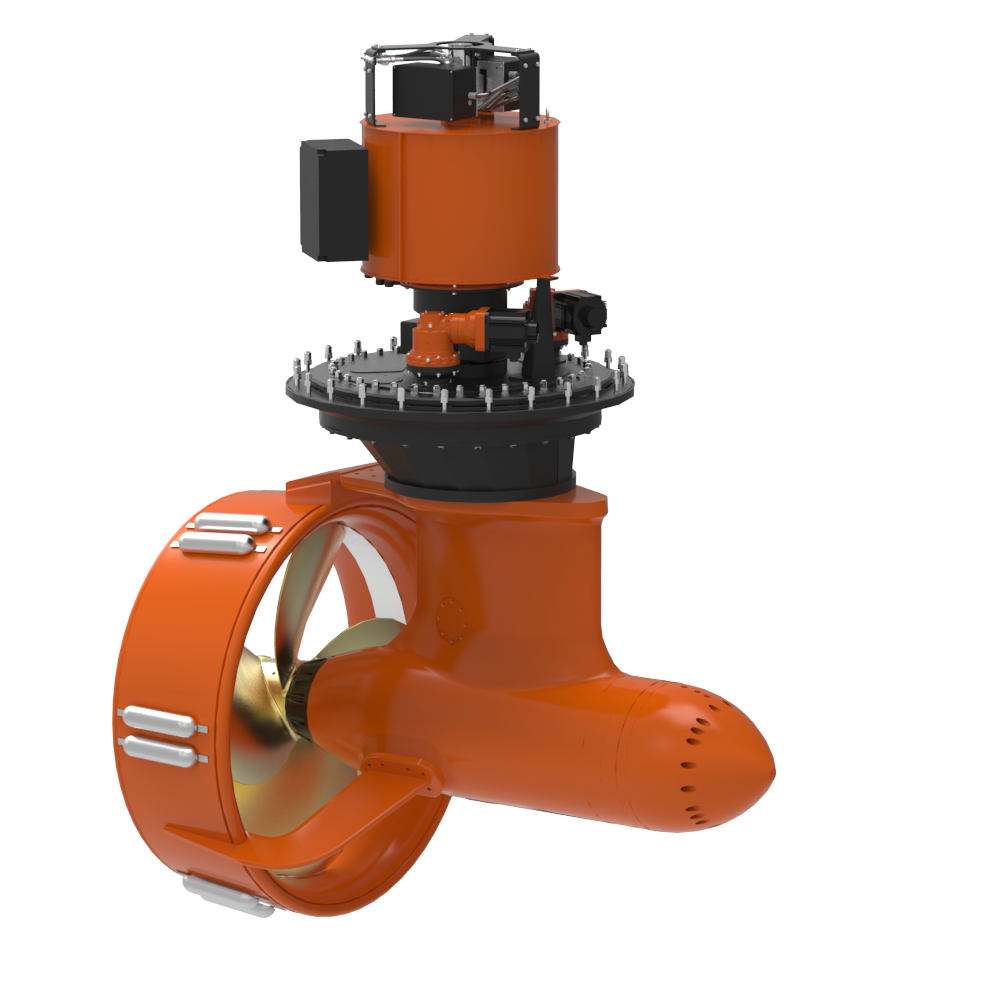

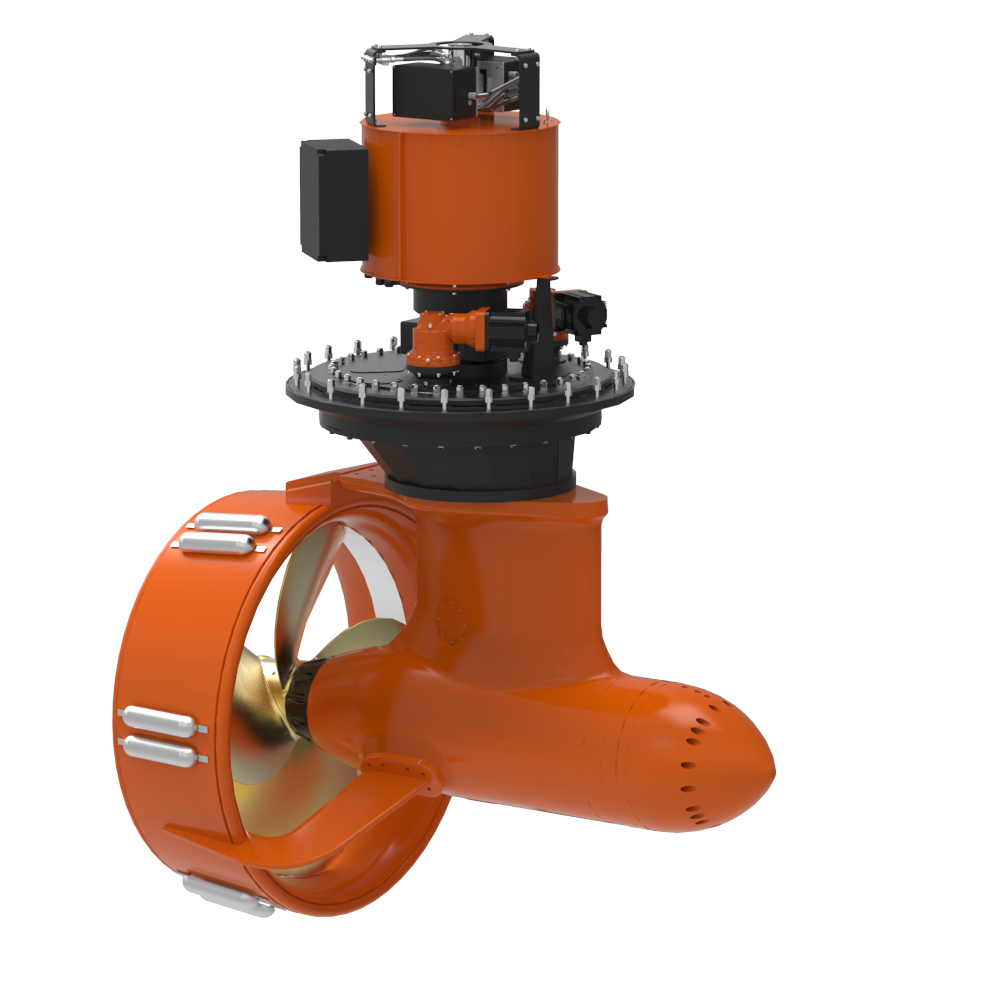

Azimuth Thrusters

360° rotating Azimuth thrusters are used when enhanced maneuverability is required in applications such as dynamic positioning, ship escort, and ship docking services.

Azimuth Thrusters

360° rotating Azimuth thrusters are used when enhanced maneuverability is required in applications such as dynamic positioning, ship escort, and ship docking services. Portable Dynamic Positioning

Quick dock-side conversion of any vessel to DP-0 thru DP-3 per any of the major classification societies.

Portable Dynamic Positioning

Quick dock-side conversion of any vessel to DP-0 thru DP-3 per any of the major classification societies. Outboard Propulsion Units

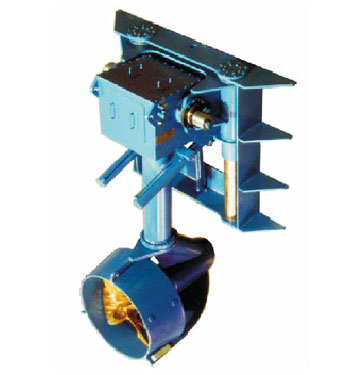

Outboard propulsion units are self-contained thruster packages for main propulsion and positioning of barges, platforms and river craft.

Outboard Propulsion Units

Outboard propulsion units are self-contained thruster packages for main propulsion and positioning of barges, platforms and river craft. Retractable Thrusters

Thrustmaster retractable thrusters are thru-hull azimuthing thrusters using fixed pitch propellers at variable speed.

Retractable Thrusters

Thrustmaster retractable thrusters are thru-hull azimuthing thrusters using fixed pitch propellers at variable speed. Water Jets

Axial flow water jets from 100kW to 6,400 kW available in 15 model sizes to accommodate vessels from 6m to +60m with stainless steel jets supported by electronic controls.

Water Jets

Axial flow water jets from 100kW to 6,400 kW available in 15 model sizes to accommodate vessels from 6m to +60m with stainless steel jets supported by electronic controls. Tunnel Thrusters

Tunnel thrusters for docking, slow speed maneuvering, emergency steering, and station keeping at zero or slow forward speeds.

Tunnel Thrusters

Tunnel thrusters for docking, slow speed maneuvering, emergency steering, and station keeping at zero or slow forward speeds. Portable River Ferry

Turn-key modular package comprised of interlocking barge sections with ramps on both ends, self-contained hydraulic outboard propulsion units, a raised pilot house, and all necessary accessories.

Portable River Ferry

Turn-key modular package comprised of interlocking barge sections with ramps on both ends, self-contained hydraulic outboard propulsion units, a raised pilot house, and all necessary accessories. Hybrid Propulsion Systems

Turn-key patented and proven hybrid propulsion packages offering a seamless integration with the vessel. Designs tailed to the vessel size, speed, transit route, and operational profile.

Hybrid Propulsion Systems

Turn-key patented and proven hybrid propulsion packages offering a seamless integration with the vessel. Designs tailed to the vessel size, speed, transit route, and operational profile. T-Pod Electric Podded Thrusters

Thrustmaster T-Pods are configured with a permanent magnet motor directly driving the propeller shaft in a pod housing.

T-Pod Electric Podded Thrusters

Thrustmaster T-Pods are configured with a permanent magnet motor directly driving the propeller shaft in a pod housing. Floatmaster

Floatmaster is a sister company of Thrustmaster of Texas, Inc., a world recognized designer and manufacturer of marine propulsion systems.

Floatmaster

Floatmaster is a sister company of Thrustmaster of Texas, Inc., a world recognized designer and manufacturer of marine propulsion systems.

-

-

Applications

-

Company

-

About Us

Thrustmaster Corporate Brochure

Thrustmaster of Texas, Inc. manufactures heavy duty commercial marine propulsion and thrusters. The factory and production of all thrusters is based out of Houston, Texas with a global network of sales offices in Rotterdam, Singapore, China, Dubai, and Brazil. A service office is located in Houma, Louisiana to assist offshore clients.All thrusters are developed in-house by a complete engineering department for mechanical, hydraulic, electrical and electronic design. Tooling includes machining and measuring equipment, CAD, vessel resistance and propulsion, 3D modeling and ANSYS Finite Element Analysis. The application of modal analysis, stress and strain analysis as well as rotor dynamic analysis of drive trains and transmissions are fundamentals towards the reliability and quality of Thrustmaster’s products.

Learn More > | Our History > | Our Facility >ContactPhone - 713-937-6295

Thrustmaster of Texas, Inc.

6900 Thrustmaster Drive

Houston, Texas 77041 USA

-

- News

- eThrust

- Contact

- Customer Support