A bow thruster used for docking and undocking should be capable of producing thrust in pounds of force (lbf) equal to twice the lateral cross sectional vessel area below the water in square feet or two to three times the lateral cross sectional area of the superstructure above the water, whichever is greater.

Sizing of tunnel thrusters for slow speed maneuvering and station keeping depends greatly on the vessel operating parameters. Before making your final selection, consult your naval architect or one of Thrustmaster’s application engineers.

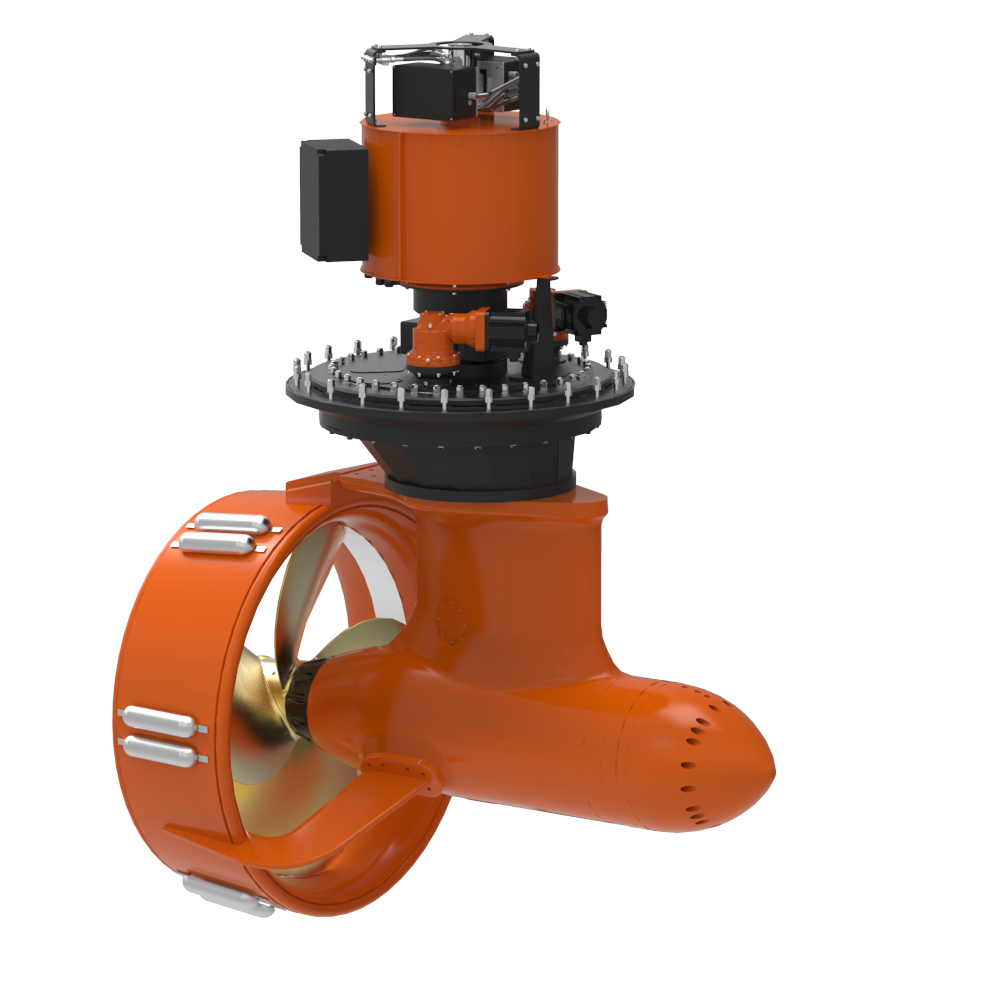

When using tunnel thrusters in waters with high current or while the vessel has forward speed, the thruster becomes less effective. At vessel speeds of 3 knots, the tunnel thruster may lose as much as 25 percent of its thrust. At speeds of 7 knots, the thruster may only produce half of its rated thrust. A Thrustmaster retractable azimuthing thruster may be more appropriate for these applications.

Tunnel thrusters need to be placed below the waterline to prevent air ingestion. If the top of the tunnel is too close to the surface of the water, vortexes may develop, resulting in air from the surface being sucked into the tunnel. This causes airlock, substantial reduction in thrust, excessive noise and vibration, and severe shock leading to the thruster. Consider the vessel draft in unloaded vessel condition. If the thruster is to be used out in open seas, consider vessel heave and roll and consider wave action in determining how far below the waterline your thruster needs to be placed to prevent air ingestion. (See also Tips on Thruster Installation)

If space does not allow proper submergence with a single tunnel thruster on a shallow draft vessel, two or more smaller tunnel thrusters, installed side by side, may be used. Multiple Thrustmaster tunnel thrusters can be powered by a single prime mover with a common hydraulic system, making the thrusters act in unison as if they were a single thruster.